Proceso De Fase Líquida

El líquido de condensación de la hexamina, después de la filtración será bombeado a la caldera de evaporación. La caldera de evaporación se mantiene con un cierto grado de vacío.

PDF Download

PDF Download

Especificación del producto

Hexamina Según estándar nacional chino GB / T9015-1998

Apariencia: cristales de colores claros o blancos sin impurezas visibles.

Cuota de consumo (como por tonelada de producto de hexamina)

Hexamina Según estándar nacional chino GB / T9015-1998

Apariencia: cristales de colores claros o blancos sin impurezas visibles.

| Elemento | Superior | Primer grado | Aceptable |

|---|---|---|---|

| Pureza % ≥ | 99.3 | 99.0 | 98.0 |

| Humedad % ≤ | 0.50 | 1.0 | |

| Cenizas % ≤ | 0.03 | 0.05 | 0.08 |

| Apariencia de solución acuosa | Acceptable | — | |

| Metal pesado como Pb2+ % ≤ | 0.001 | — | |

| Cloruro como Cl- % | 0.015 | — | |

| Sulfato como SO42- % ≤ | 0.02 | — | |

| Amonio como NH4+ % ≤ | 0.001 | — | |

Package:packed with film plastic bags, then wrapped in woven bags or other applicable package material, net weight of each bag: 25kg; stored in dry, clean and well ventilated warehouse, stored outdoors prohibited, prevented from wetting. The following info. shall be marked on bags: brand, standard no., manufacturer, product name, production lot, net and FMR marks.

Cuota de consumo (como por tonelada de producto de hexamina)

| S/N | Particular | Unidad | Cuota de consumo | Observación |

|---|---|---|---|---|

| 1 | Formalin (37%) | t | 3.5~3.6 | |

| 2 | Amoniaco (100%) | kg | 530~550 | |

| 3 | Agua de enfriamiento en circulación | t | 250~300 | Temperatura del agua .≤25℃ P≥0.4MPa |

| 4 | Vampor | t | 7.0~8.0 | P≥0.4MPa |

| 5 | Electricidad | kW·h | 180 | 380/220V 50Hz |

| 6 | Agua desmineralizada | t | 1~2 | Según la norma de D.W. |

| Project | Type and parameter | Production line | Finish date |

|---|---|---|---|

| Qinghai Haihong Chemical Co., Ltd | 50000tpa Hexamine Plant | 1 | 2009.5 |

| Qingzhou hengxing Chemical Co., Ltd | 5000tpa Hexamine Plant | 1 | 2010.5 |

| Lanzhou Petrochemical methanol industry | 5000tpa Hexamine Plant | 1 | 2010 . 9 |

| Fuhua Tongda Agro-chemical Technology Co., Ltd | 10000tpa Hexamine Plant | 1 | 2013.6 |

Overview - Liquid Phase Process

Hexamine is fully called hexamethylenetetramine. The structural formula is (CH2)6N4,and the molecular weight is 140.19,The main material for hexamine production is formaldehyde and ammonia. There are two kinds of production technologies: liquid phase and gas phase process.Hexamine is made from the condensation of formaldehyde and ammonia in the alkaline solution. The reaction equation is as belows,6CH20+4NH3 =(CH2)6N4+6H2O+339×103J/mol

From the reaction, hexamine is reacted from 6 formaldehyde elements and 4 ammonia elements to 1 hexamine element and 6 water elements, with heat of 339×103J/mol. In the real production, to make the reaction prefers hexamine, and avoid side reaction and big consumption, the reaction temperature and ammonia excess should be well controlled. That is to say, the free ammonia is made to exist in the reaction solution, to prevent the reverse reaction and resist forming trimethylamine, for trimethylamine has stink and affect the product purity.

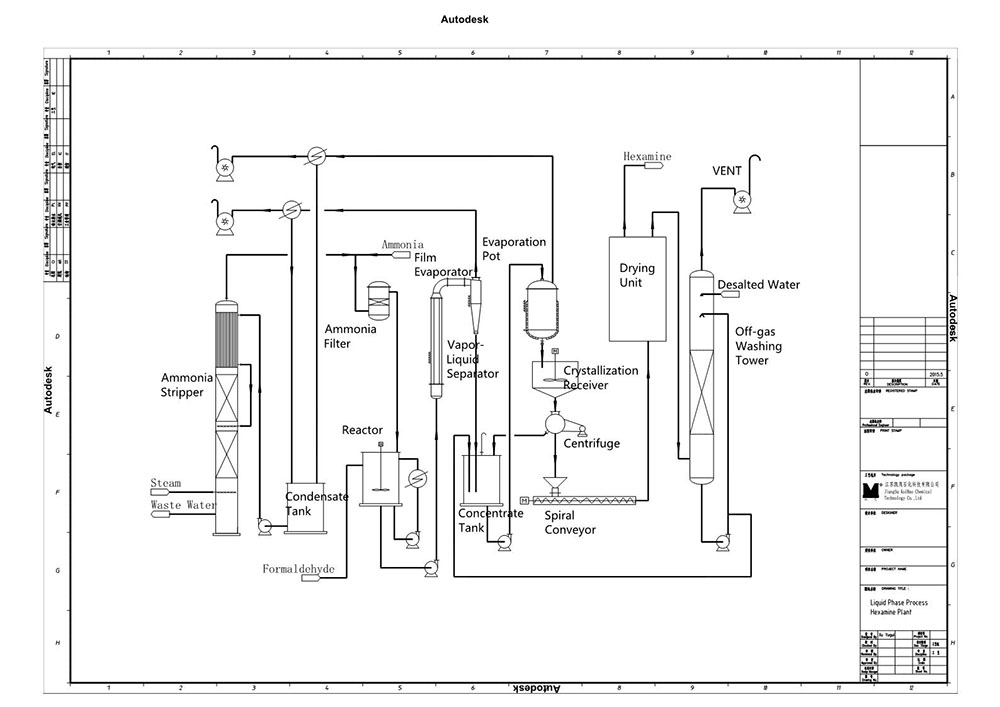

The technological process is divided into the condensation reaction of formaldehyde and ammonia, the hexamine evaporation, condensation, centrifuge and drying.

Ammonia via filtration and liquid formaldehyde are collocated as a certain scale (ammonia excess 0.8-1.2%) and come to reactor. The reaction synthesis hexamine content is 24-27%, and the reaction synthesis heat is moved out from the circulation cooler, keeping the reaction temperature 60-65℃. The reaction hexamine solution is put to the film-type evaporator, condensed to 60-65%. Water is condensed by the cooler. The whole condensation process is pumped by the vacuum pump with negative pressure. The condensation liquid is put to evaporation boiler, continuously get dewatered and condensed in vacuum. When the crystallized granule forms, it will be sent to the centrifuge for mother liquid separation. The solid material is put to air-flow dryer, via cyclone separator for separation, getting product of hexamine.

Brief introduction on the process:

1.The Reaction unit

Ammonia is put from the outer boundary, or the gas ammonia is gasified by liquid ammonia from the liquid ammonia evaporator. The ammonia, with control valves controlling the flow, comes into the reactor bottom, having bubbling reaction. The formaldehyde solution and ammonia gas have reaction in the reactor, making hexamine solution. The reaction liquid is controlled in the certain PH range.

2. The condensation unit

The reaction liquid is pumped to Film Evaporator,have it heated by steam. The gas and liquid after evaporation comes into cyclone separator. The hexamine condensation liquid from the cyclone separator bottom flows to Concentrate Tank. The gas is pumped out by vacuum pump, via condensation, it will comes to Condensate Tank

The liquid from the Condensate Tank is pumped to Evaporation Pot, heated by steam. The Evaporation Pot will be kept a certain vacuum degree. After the water of evaporation boiler evaporated, hexamine crystal will be formed. When the crystal reaches to a certain concentration, the heating will be stopped, and the emptying valve and discharge valve of the boiler bottom will be switched on. The hexamine and mother liquid will be put to the suction filter tank or centrifuge for spin-drying. There is litter ammonia in the gas, and will be pumped by the vacuum pump. After condensation, it will be sent to Condensate Tank.

Hexamine condensation concentration is controlled by the feeding material quantity and the heating steam. Normally the concentration of the condensation liquid is controlled about 38%.

Hexamine condensation liquid, after filtration will be pumped to evaporation boiler. The evaporation boiler keeps to a certain vacuum degree. The evaporated gas includes little ammonia, after condensation, it comes to Condensate Tank. After the water from evaporation boiler gets evaporated, hexamine will become crystal. When the crystal reaches to a certain concentration, the heating will be stopped and the emptying valve and material discharging valve of the boiler bottom will be switched on. Hexamine and the mother liquid will be put to the suction filter tank or centrifuge for spin-drying. The mother liquid will flow into mother liquid tank, and then pumped by the mother liquid pump to the mother liquid elevated tank, via filtration, then flow into evaporation boiler for dewatering.

After dewatering, hexamine with water content of 3~5% is sent to the drying system, The air-flow dryer or vibratory fluidized-bed is used for drying and discharging with hexamine content of 99.3%. Finally the finished product via weighing and packing will be sent for storage.

The liquid phase reaction and evaporation are all continuously operated; the evaporation boil is with batch operation, heavy labor and lots of waste water.

Because the liquid formaldehyde and condensation batch operation are adopted, impurities and side reactions are brought to the production, which will affect the product purity, thus the mother liquid filtration equipment is a must in the process.

Hexamine is fully called hexamethylenetetramine. The structural formula is (CH2)6N4,and the molecular weight is 140.19,The main material for hexamine production is formaldehyde and ammonia. There are two kinds of production technologies: liquid phase and gas phase process.Hexamine is made from the condensation of formaldehyde and ammonia in the alkaline solution. The reaction equation is as belows,6CH20+4NH3 =(CH2)6N4+6H2O+339×103J/mol

From the reaction, hexamine is reacted from 6 formaldehyde elements and 4 ammonia elements to 1 hexamine element and 6 water elements, with heat of 339×103J/mol. In the real production, to make the reaction prefers hexamine, and avoid side reaction and big consumption, the reaction temperature and ammonia excess should be well controlled. That is to say, the free ammonia is made to exist in the reaction solution, to prevent the reverse reaction and resist forming trimethylamine, for trimethylamine has stink and affect the product purity.

The technological process is divided into the condensation reaction of formaldehyde and ammonia, the hexamine evaporation, condensation, centrifuge and drying.

Ammonia via filtration and liquid formaldehyde are collocated as a certain scale (ammonia excess 0.8-1.2%) and come to reactor. The reaction synthesis hexamine content is 24-27%, and the reaction synthesis heat is moved out from the circulation cooler, keeping the reaction temperature 60-65℃. The reaction hexamine solution is put to the film-type evaporator, condensed to 60-65%. Water is condensed by the cooler. The whole condensation process is pumped by the vacuum pump with negative pressure. The condensation liquid is put to evaporation boiler, continuously get dewatered and condensed in vacuum. When the crystallized granule forms, it will be sent to the centrifuge for mother liquid separation. The solid material is put to air-flow dryer, via cyclone separator for separation, getting product of hexamine.

Brief introduction on the process:

1.The Reaction unit

Ammonia is put from the outer boundary, or the gas ammonia is gasified by liquid ammonia from the liquid ammonia evaporator. The ammonia, with control valves controlling the flow, comes into the reactor bottom, having bubbling reaction. The formaldehyde solution and ammonia gas have reaction in the reactor, making hexamine solution. The reaction liquid is controlled in the certain PH range.

2. The condensation unit

The reaction liquid is pumped to Film Evaporator,have it heated by steam. The gas and liquid after evaporation comes into cyclone separator. The hexamine condensation liquid from the cyclone separator bottom flows to Concentrate Tank. The gas is pumped out by vacuum pump, via condensation, it will comes to Condensate Tank

The liquid from the Condensate Tank is pumped to Evaporation Pot, heated by steam. The Evaporation Pot will be kept a certain vacuum degree. After the water of evaporation boiler evaporated, hexamine crystal will be formed. When the crystal reaches to a certain concentration, the heating will be stopped, and the emptying valve and discharge valve of the boiler bottom will be switched on. The hexamine and mother liquid will be put to the suction filter tank or centrifuge for spin-drying. There is litter ammonia in the gas, and will be pumped by the vacuum pump. After condensation, it will be sent to Condensate Tank.

Hexamine condensation concentration is controlled by the feeding material quantity and the heating steam. Normally the concentration of the condensation liquid is controlled about 38%.

Hexamine condensation liquid, after filtration will be pumped to evaporation boiler. The evaporation boiler keeps to a certain vacuum degree. The evaporated gas includes little ammonia, after condensation, it comes to Condensate Tank. After the water from evaporation boiler gets evaporated, hexamine will become crystal. When the crystal reaches to a certain concentration, the heating will be stopped and the emptying valve and material discharging valve of the boiler bottom will be switched on. Hexamine and the mother liquid will be put to the suction filter tank or centrifuge for spin-drying. The mother liquid will flow into mother liquid tank, and then pumped by the mother liquid pump to the mother liquid elevated tank, via filtration, then flow into evaporation boiler for dewatering.

After dewatering, hexamine with water content of 3~5% is sent to the drying system, The air-flow dryer or vibratory fluidized-bed is used for drying and discharging with hexamine content of 99.3%. Finally the finished product via weighing and packing will be sent for storage.

The liquid phase reaction and evaporation are all continuously operated; the evaporation boil is with batch operation, heavy labor and lots of waste water.

Because the liquid formaldehyde and condensation batch operation are adopted, impurities and side reactions are brought to the production, which will affect the product purity, thus the mother liquid filtration equipment is a must in the process.

Productos relacionados

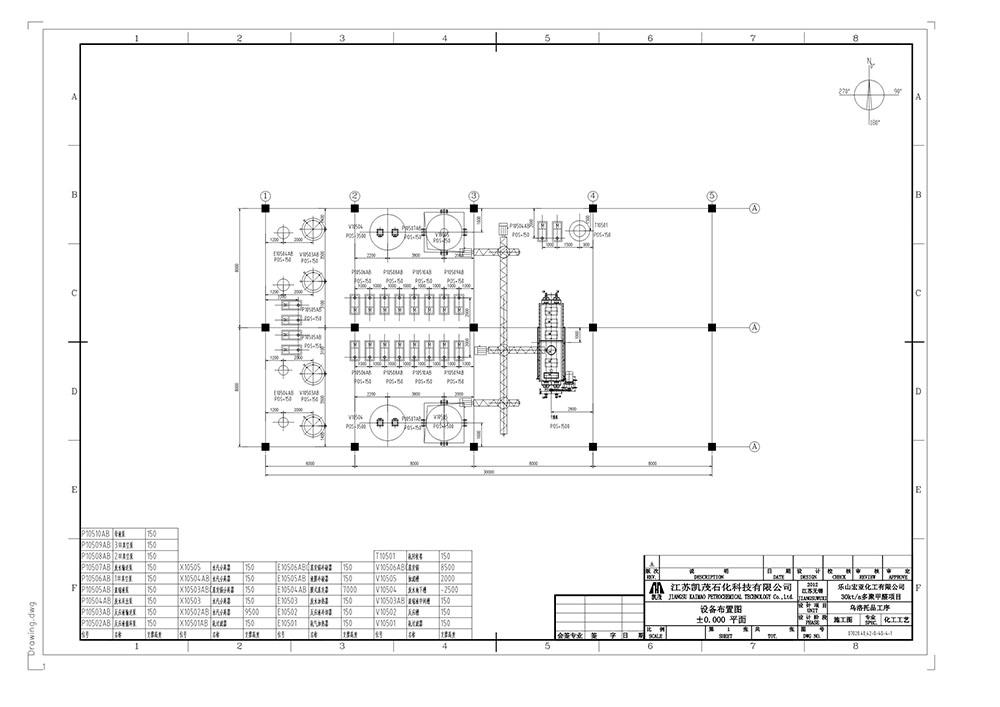

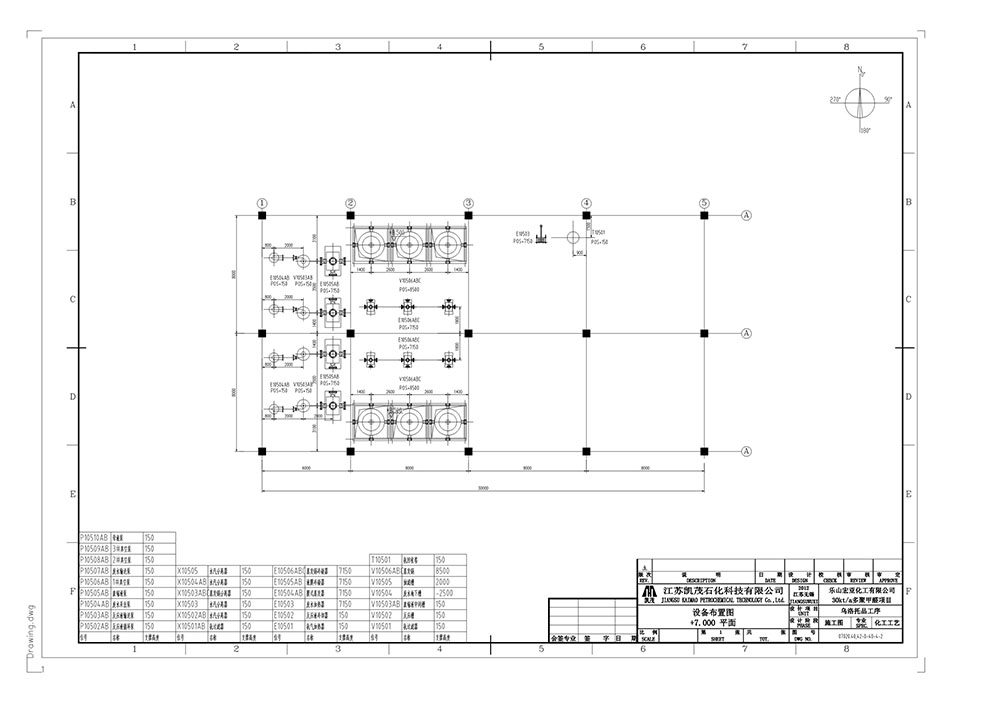

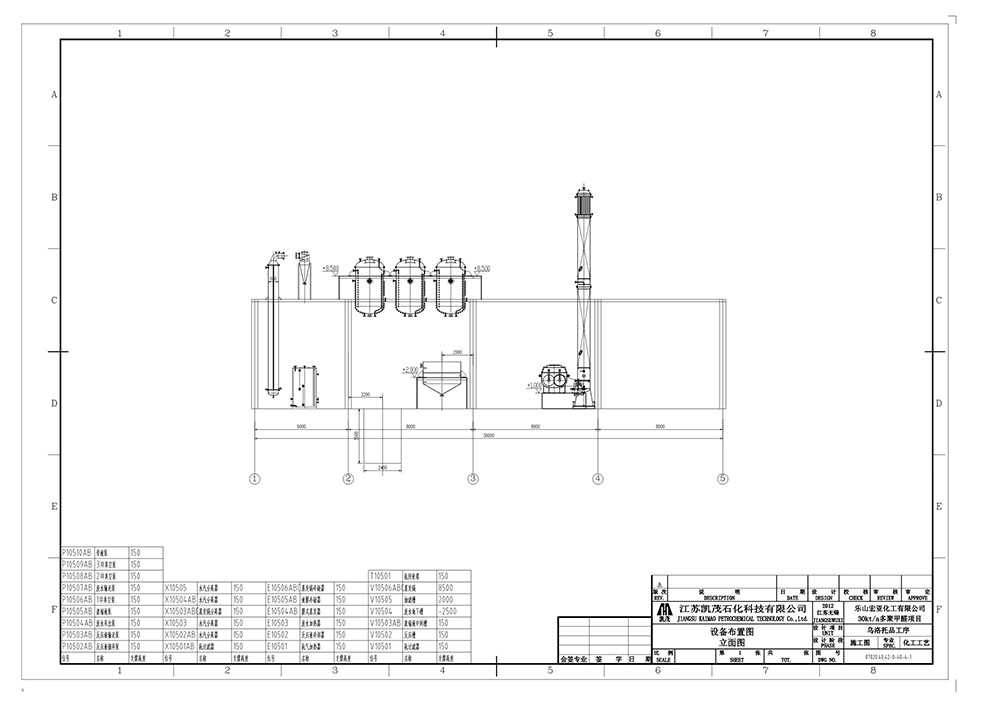

Layout Drawing

Layout Drawing